We can apply digital printing technology to our edgebanding production.

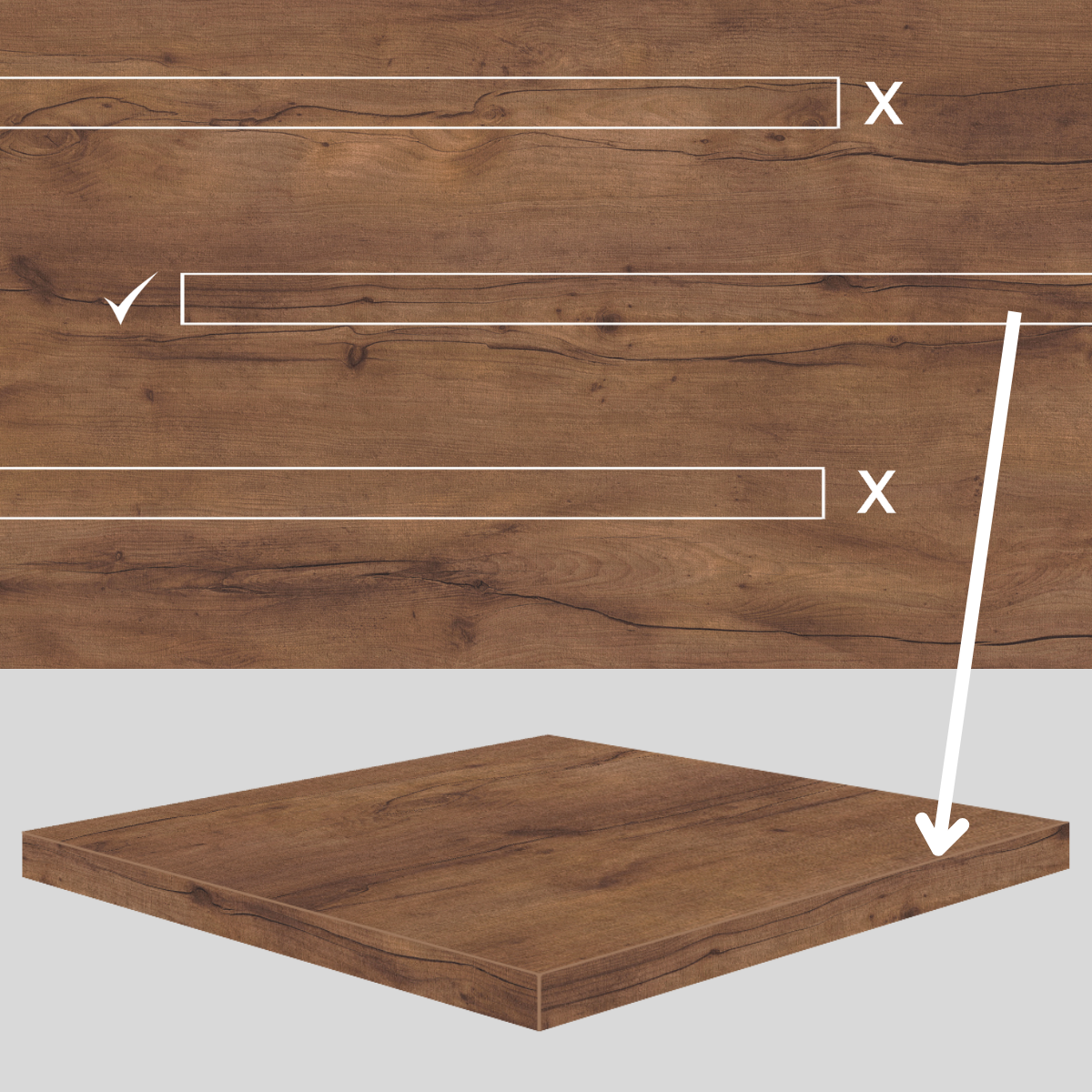

Certain designs, due to the complexity, color variation and superposed designs, cannot be optimally reproduced by means of traditional printing technology “printing rollers”. With digital printing technique, almost any design or photography can be reproduced on edgebands. Therefore, you will get the perfect match for your board.